NEWS & EVENTS

Coatings Lunch & Learn

Want to find out more about Coatings? Come to our Coatings Lunch & Learn. Call us to find out more or to register for the next class!

Want to find out more about Coatings? Come to our Coatings Lunch & Learn. Call us to find out more or to register for the next class!

Whether consulting with contractors, developers, facilities managers or architects—whatever the flooring option and no matter the project’s scope—we stay focused on one thing: a consultation process designed to deliver the best floor for your specific needs.

We first perform an onsite evaluation, analyzing the findings and consulting with you to learn everything we can. Is sanitation a concern? Is there exposure to extreme temperatures, heavy machinery, or caustic chemicals? Are aesthetics important? Or is it more important to withstand high foot traffic? Maybe both are important?

Throughout the process, we explain the options, working toward the optimum mix of durability, aesthetics, and overall value. Plus, before making our formal recommendation, we get approval from the supplier of the proposed flooring system.

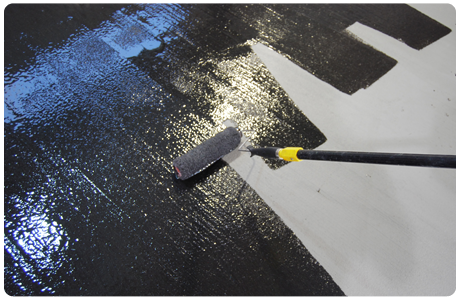

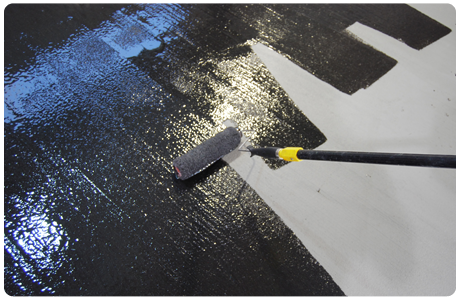

With a plan in place, we turn our attention to site preparation. We may need to demolish the existing flooring. The substrate may require an underlayment or even patches. Perhaps we’ll need to remove the base before installing a new topping or coating. We can manage any of these needs.

Close working relationships with leading suppliers ensure the selection and proper application of the appropriate polish, coating, or topping. No matter the flooring system, we stand ready with a battery of specialized equipment that includes six 3- to 4-headed diamond grinders, five Blastrac shot blasters, and numerous hand grinders, as well as an ample stock of onsite tooling. The sheer number of machines we have available prevents delays from breakdowns or multi-site jobs.

From the first walk-through to the last pass with a buffer, each new step in QC Companies’ consultation process builds on the last to ensure your satisfaction.

Rely on QC Companies when sanitation is an overriding concern. Because they are non-porous, these floors are impervious to microbes and other contaminants. That feature makes it easy to wipe up liquids, grease, grime or any other spill. It also makes these floors tough enough to endure relentless cleanings with harsh compounds and other industrial cleaning techniques. That means QC floors will withstand all the rigors of bottling plants, distilleries, and other food processing facilities.

MMA Cementitious Urethane

Non-porous, impervious flooring systems from QC Companies combine sanitation and aesthetics. That makes them perfect for a complete range of pharmaceutical facilities. Consult with us to develop and apply the right system for your R&D laboratory, manufacturing plant, vivarium cage-wash area, or any other setting with similar challenges.

MMA Epoxy & Polyurethane Cementitious Urethane

Shopping malls, supermarkets, big-box stores, and other retail facilities pose a complex set of challenges. That is why QC Companies pays special attention to developing and applying flooring systems that are attractive, durable, easily cleaned, slip-resistant, and capable of meeting a range of inspection requirements.

MMA Epoxy & Polyurethane

Floors in industrial facilities must be able to endure constant abuse and extreme impact. Let QC Companies engineer the flooring system to meet the specific demands of your factory, warehouse, or other facility. Our flooring systems withstand heavy loads, the movement of vast equipment, and constant forklift traffic. In addition, you can count on our SRS Degadur flooring to repel acids and other harsh chemicals.

MMA Epoxy & Polyurethane Cementitious Urethane

Bakeries, restaurants, hotels and other commercial kitchens must meet a battery of exacting requirements. A flooring system from QC Companies can help ensure that your facility is in compliance with relevant local, state, and federal regulatory agencies—without sacrificing aesthetics. In addition to being attractive, our flooring systems are durable, slip-resistant, stain-resistant and capable of being installed without unnecessary costly downtime. Also, with the optional antimicrobial additive, you get the extra level of protection that can be critical, especially behind equipment or in other hard-to-clean areas.

Cementitious Urethane

Durability, slip-resistance, and ease-of-maintenance combine with excellent weatherability to make QC Companies' flooring systems perfect for a wide range of sporting and other public-assembly facilities. Depend on QC Companies to develop and apply flooring systems throughout your facility. From seating areas to concourses, concession areas, restrooms, and locker rooms, you and your customers will benefit from surfaces that are clean, hygienic, attractive and resistant to spills and stains.

MMA Epoxy & Polyurethane

When the safety and hygiene of your employees and your animal patients are top priority, depend on QC Companies to supply the best flooring solution. QC floors are non-porous, which makes them impervious to microbes and biological contaminants. In addition, options are available that prevent slipping and resist the growth of bacteria and staining. These qualities deliver a floor that is easy to clean and keep looking new, even when using tough detergents. It is also highly durable, with a surface that stands up to whatever hits it. Because of the non-slip feature, staff as well as sick or injured animals will be able to walk with confidence on a QC floor. In addition, if an animal claw should leave a gouge, it can be repaired easily with a spot application of the resin that composes the floor. All of this means that a QC floor is the ideal flooring system for Veterinarian & Boarding environments.

MMA

If you need to keep a project moving, even when moisture is a concern, or if your floor will face extra punishment, QC Companies may recommend cementitious urethane.

Rely on cementitious urethane to withstand abuse better than acid brick, quarry tile—or virtually any other surface or coating. Thanks to its seamless, monolithic surface, it can endure prolonged, repeated assaults from harsh chemicals or extreme temperature swings. You may add metallic aggregate to the resin to further fortify against physical punishment. Available antimicrobial admixtures reduce the risk of contamination.

Cementitious urethane works either as an overlay in new construction or to resurface floors in existing facilities. In addition, it handles moisture so well that QC Companies can apply it to seven-day-old concrete, without a moisture control system.

Several qualities unite to make cementitious urethane flooring systems ideal for settings where cleanliness is critical.

Its ability to endure corrosive chemicals means cementitious urethane will hold up under relentless cleanings with harsh compounds. That same hardiness also lets it withstand live steam and other industrial

cleaning techniques. Also, between cleanings, cementitious urethane’s impervious, monolithic surface inhibits the growth of fungi, mold and bacteria such as E. coli and salmonella. This feature makes it an especially effective flooring system for food and beverage production, as well as for any wet environment.

To further ease concerns about contamination or chemical degradation, rely on QC Companies for the cementitious urethane application that stands up to your facility’s precise demands.

In many commercial, industrial, and even institutional settings, aesthetics can be just as important as durability. That is why QC Companies often recommends epoxy and polyurethane as the flooring option that can withstand high traffic, high impact, and high design expectations.

Epoxy and polyurethane floors offer a more economical, more durable alternative to tile, carpet, linoleum, or other options. As it cures, its resins form a seamless surface that resists abrasions, stains, and chemical spills, making it easier to clean and maintain.

Not only cost leads QC Companies to recommend epoxy and polyurethane floors for everything from schools and malls to factories and warehouses. The wide choice of available quartz chips, flakes, and color pigments opens up almost endless design options. Custom blend your flooring system to achieve almost any aesthetic effect, including glow in the dark, black-light, or an earthy warmth similar to natural stone.

Getting the most from your epoxy and polyurethane floor starts with QC Companies. For each distinct step in the application process, QC Companies brings the specialized equipment and know-how to ensure your floor keeps delivering its many benefits for years to come.

Since moisture can be an ongoing problem, QC Companies stands ready to address anything from a single patch to a full moisture control system. Consult with us to assess the problem, formulate a solution, select the most effective product, determine the application process, and—finally—apply the moisture control system.

Our solutions can be used over existing concrete whenever moisture emissions exceed the maximum allowed by a floor covering manufacturer. To determine whether emissions are acceptable, QC Companies uses either a hygrometer to measure relative humidity or a calcium chloride test to gauge the rate of evaporation.

As with all our moisture control systems, we use products that consist of fast curing, 100 percent solids epoxy – the only compound proven effective for controlling moisture. That means you can count on the product we select to limit evaporation and trap in moisture for the life of the floor. By trapping moisture in, we also keep water out. That makes the concrete slab resistant to both water and frost.

QC Companies may recommend MMA for floors whenever durability, ease-of-repair, or reducing downtime are concerns.

Incomparable color stability, thanks to near-total resistance to UV light, is just one of MMA’s unique traits. Unlike other polymer flooring systems, MMA absorbs only trace amounts of UV radiation, far too little to degrade molecular bonds.

When applied, resins in the liquid permeate the concrete, creating a welded bond as the liquid cures. The result is a seamless, non-porous surface. Not only will that surface resist impact, stains, and even chemical spills, it will not chalk, delaminate or become brittle.

MMA’s unique properties also simplify maintenance and repairs. Since its resins reactivate when exposed to liquid MMA, it takes only a spot application to fix the occasional gouge.

Beyond these benefits, MMA combines function with aesthetics, offering a selection of quartz chips, flakes, and color pigments. Additional options can prevent slipping, resist bacteria, and withstand extreme and rapid temperature changes.

Compare MMA’s one-hour cure time—even in temperatures as cold as -20F—to the 8- to 24-hour cure times of other coatings. By reducing application time, MMA limits lost revenue from excessive downtime. Plus, low levels of volatile organic compounds (VOCs) and a solvent-free application process can reduce costs even more, by requiring fewer health and safety precautions.

Letting QC Companies assess the need for moisture control can accelerate production schedules, prevent costly problems and extend the life of new concrete.

To identify problem areas and appropriate treatments, QC Companies starts by taking a moisture reading. We may use a hygrometer to measure relative humidity. To gauge the rate of evaporation, we may also perform a calcium chloride test instead.

Depending on our findings—as well as on your production schedule or other needs—we may focus on a problem area, such as a visible wet spot. Sometimes, we may recommend treatment for an entire slab.

Applying moisture control directly to the concrete substrate can prevent floor toppings, coatings, or polishes from being damaged by any residual moisture or alkaline in the concrete. This can be especially useful when moisture remains in completely cured concrete, yet you must keep the project on schedule. Even with relative humidity as high as 98 percent, our moisture solutions can let you safely and quickly move to the next step, applying any thickness of underlayment or topping.

No matter the situation, QC Companies uses only products that consist of 100 percent solids epoxy. That is the only compound proven effective for controlling moisture. Count on whatever product we select to limit evaporation and to trap in moisture for the life of the floor.

For badly battered substrates, QC Companies sometimes recommends engineered cement patches. Addressing problems like pop-outs, spalls, and corrosion before applying the underlayment ensures the successful installation of vinyl, ceramic tile, carpet, linoleum, vinyl composition tile (VCT), or other types of floor.

Using trowel-applied engineered cement patches, QC Companies can smooth the surface of the roughest concrete, ceramic tile, terrazzo and, in special applications, wood. Whatever the substrate, rely on QC Companies to deliver a surface that is durable, smooth and flat—all within tolerance of project specifications.

Self-drying formulations, like those available from Ardex, do more than just dry fast. Because they are engineered to hydrate all of their mix water, these patches cure without any evaporation. That feature, along with its high pH value and the absence of any organic material, means engineered cement does not contribute to staining, mold, mildew, or other problems that can result from excess moisture.

QC Companies knows how to give your concrete floor the look, feel and durability of polished stone, all for less than the cost of wood, quality carpeting, or natural stone such as granite, limestone, marble, or slate.

QC Companies starts the multi-step process by grinding, treating, and—ultimately—polishing the concrete to a high gloss. By increasing surface density, polishing also eliminates dusting and produces a surface that repels oil, water, and other substances. It can enhance resistance to scrapes, scuffs, and abrasions, and it can even dramatically reduce skid marks from forklift tires.

Beyond just enhancing durability, polishing brightens unfinished concrete and turns production areas and drab warehouses into client showplaces. Surprisingly, despite its slick appearance, polished concrete actually reduces the risk of slips, falls and related accidents. In fact, polished concrete exceeds the slip coefficient standards set forth in the Americans with Disabilities Act.

Low environmental impact is one more thing that makes polished concrete worth considering. Because you are restoring existing concrete instead of tearing it out, you’re reducing waste. Polished concrete also lasts longer than other methods of restoring concrete. Plus, eliminating the adhesives needed for flooring such as carpet or vinyl gives contractors the opportunity to earn LEED credits.

Polished concrete is not just more durable and more attractive. It is also more economical.

The savings start with its low initial costs. And, because it requires so little maintenance, it also reduces lifecycle costs. The attractive, high-gloss finish can even reduce ongoing lighting cost by reflecting ambient light.

Rely on QC Companies to recommend the polished topping and process best able to revitalize your existing concrete floor.

QC Companies brings expertise to each stage of the process, from mechanical preparation of the concrete, to application of the cementitious topping, selection of the finishing treatment, and—finally, to polishing the new surface.

To ensure proper preparation of the substrate, QC Companies first carefully and completely removes any previous coating, adhesive, or other residue. We then grind the concrete, patching where needed.

Application begins only when the substrate is sound, solid, and clean. Once we have applied the cementitious topping and ensured that it has cured properly, we polish, using the appropriate finishing treatment. Throughout the process, our operators draw on years of experience to select the proper tooling—expertly refining the diamond grit to achieve the desired gloss.

You can depend on your polished topping concrete floor to repel stains, resist abrasions, and be free from dusting. In addition, polished toppings allow the transmission of water vapors, which can prevent the failure that can occur with vinyl, coating, and other flooring options.

This cost-effective alternative to replacing the slab does more than just dramatically reduce maintenance and extend the life of your floor. A complete range of colors and textures allow unique decorative effects. Also, the resulting highly reflective surfaces can reduce lighting costs by increasing ambient light. Add it up, and you get a lifecycle cost lower than almost any other type of flooring.

Consult with QC Companies when you seek a fast and simple way to add a full range of design effects. Engineered cement toppings can be an economical way to achieve a concrete floor that is durable, low-maintenance, smooth, and flat. We can help determine if a topping is the best option for your concrete floor.

Rely on QC Companies to use engineered cement toppings to bring out the luster of the natural concrete gray. Or, when specified, QC Companies can create unique looks by integrating brilliant color resins into the engineered cement during application. Add a logo or other custom design by using decorative inlays or by staining the cured topping prior to sealing.

Because engineered cement is self-leveling, you get a flat, smooth surface without the added labor cost of trowel-applied toppings. Even though engineered cement dries quickly, manufacturers such as Ardex offer self-drying formulations that further eliminate problems from excess moisture. By hydrating all of their mix water, these engineered cements cure without any evaporation.

QC Companies knows that an engineered cement underlayment can be a critical first step when installing vinyl, ceramic tile, carpet, linoleum, vinyl composition tile (VCT), or other type of flooring.

Whether your substrate is concrete, terrazzo, ceramic tile, quarry tile, epoxy, or another material, an engineered cement underlayment can ensure the success of the entire project. That is because this fast-track leveler delivers a flat, smooth surface that is assigned to be well within tolerance of project specifications. Engineered cement can also be featheredged, so that it stays level right up to the edge, no matter how craggy the substrate.

Applying an engineered cement underlayment does not add costly downtime. Rely on it to harden and dry quickly, all without the risk of shrinking, cracking, or spalling.

As an added benefit, engineered cement’s high pH value and complete lack of organic material means that, once installed, this durable compound resists the microbes that can cause mold, mildew, and other problems.